PAINTING FENCES

POWERCOLOR works on all types of structures: gates / pillars / railings / nets / different structures / roof tunnels / gazebos

PAINTING OF PANELS

Powder coatings for different uses: roof panels / highway panels for soundproofing / heavy panels

HEAVY AND LIGHTWEIGHT STRUCTURES

We can paint different types of structures: shelving of various weights and types / structures for lifts / conveyor belts

INDUSTRIAL FURNITURE

Powder coating solutions for industrial furniture: containers / tables / chairs / electrical panels / aluminum profiles / frames and structures for windows and doors

VARIOUS MACHINERY

Solutions for all the paintable parts of a machinery: frames / various roller conveyors / agricultural machinery / earth moving machinery / wood splitters

BUILDING STRUCTURES

We can guarantee painting solutions for heavy industry: beams / HPE / UNP / trusses / heavy duty structures / heavy shelving

We are able to satisfy the most diverse types of paintable structures

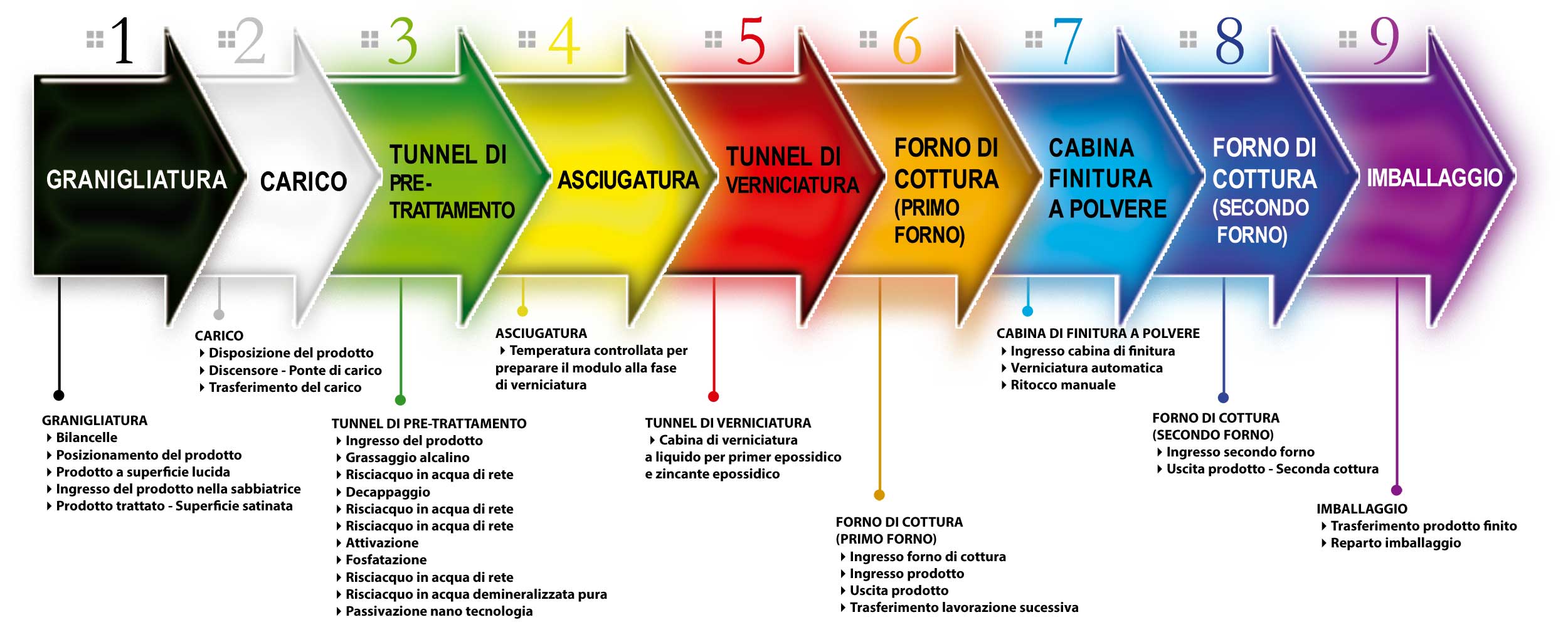

All Powercolor processes go through specific production phases of powder or liquid painting.

The continuous research to offer the customer the best solution to the problems of powder coating, has led us to the installation of a technologically advanced system, which is the result of the combined synergy between POWERCOLOR and some research and development companies of automated industrial systems.

Thanks to this collaboration, POWERCOLOR has activated the 1st fully automated system in the NORTH-EAST of Italy which guarantees the highest quality in processing and compliance with delivery times for both limited and large quantity orders.

Certified quality

Production phases

All the powder or liquid painting processes performed by Powercolor pass through specific PRODUCTION PHASES.

THE POWDER PAINTING SYSTEM HAS A MAXI FORMAT:

8000 X 2400 X 1200 MM

All processes are also followed and controlled by a staff specialized in quality control of each single powder-coated piece

Each phase is monitored

Powercolor buys from the most important and qualified Italian and European powder coatings manufacturers. With their Research Center laboratory, it maintains constant relationships for the continuous improvement of powders and chemicals already used or for the search for new solutions.

Furthermore POWERCOLOR offers the possibility to carry out chemical / mechanical resistance tests in compliance with European standards.

- Chemical resistance tests

- Mechanical resistance tests

- Specific measurements

Chemical resistance tests

- Salt spray chamber exposure

(UNI ISO 9227); - Exposure in a humidostatic chamber

(UNI 8744).

Mechanical resistance tests

- Mechanical tests of Erichsen padding (UNI 8900);

- Impact resistance tests or impact tests (UNI 8901);

- Bending tests with conical mandrel (UNI ISO 1519);

- Grid or grid adherence tests (UNI EN ISO 2409).

Other tests and measurements

- Measure brilliance (UNI 9389);

- Coating thickness measurement (UNI ISO 2360);

Italiano

Italiano